Description

In order to be able to produce open form coils , 5 different work steps are required. We have implemented these work sequences in 5 machines or devices. These are to be set individually so that only these devices are required.

A high level of economic efficiency of the device is guaranteed, since the dimensions and dimensions of the open form coils can be variably adjusted. Furthermore, wave windings and loop windings can be bent.

The set-up times are between 15 and 25 minutes.

We have divided the main operations as follows.

- Straighten and cut flat wire

- Stripping the wire ends

- Bending the hairpin

- Deflection of the coil (wave winding or loop winding)

- involute bend

Compilation of possible individual machines to produce open form coils:

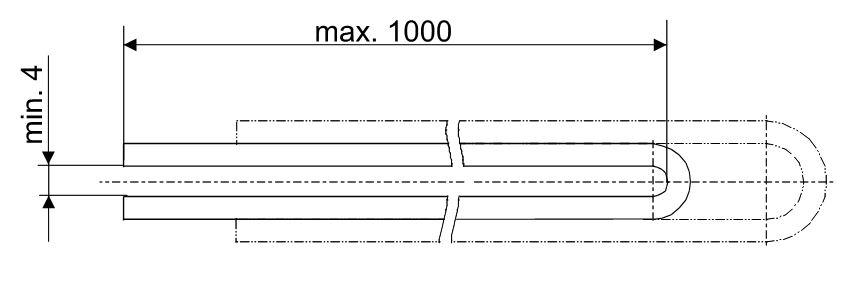

| 3.065.10 | straightening and cutting machine; cutting length max. 2000mm |

| 3.065.11 | straightening and cutting machine; cutting length max. 3000mm |

| 3.065.12 | straightening and cutting machine; cutting length max. 4000mm |

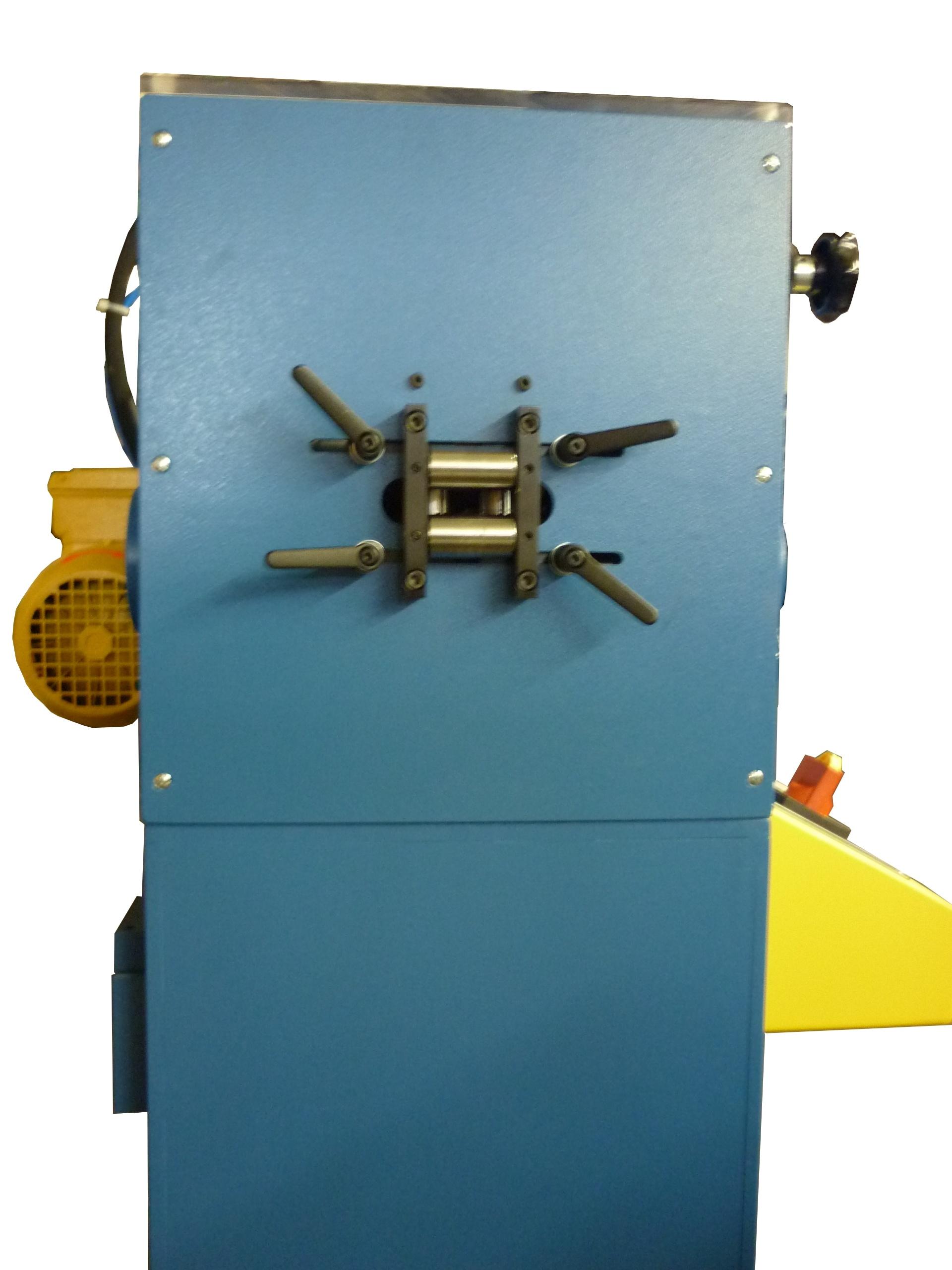

| 5.086.10 | Stationary stripping machine |

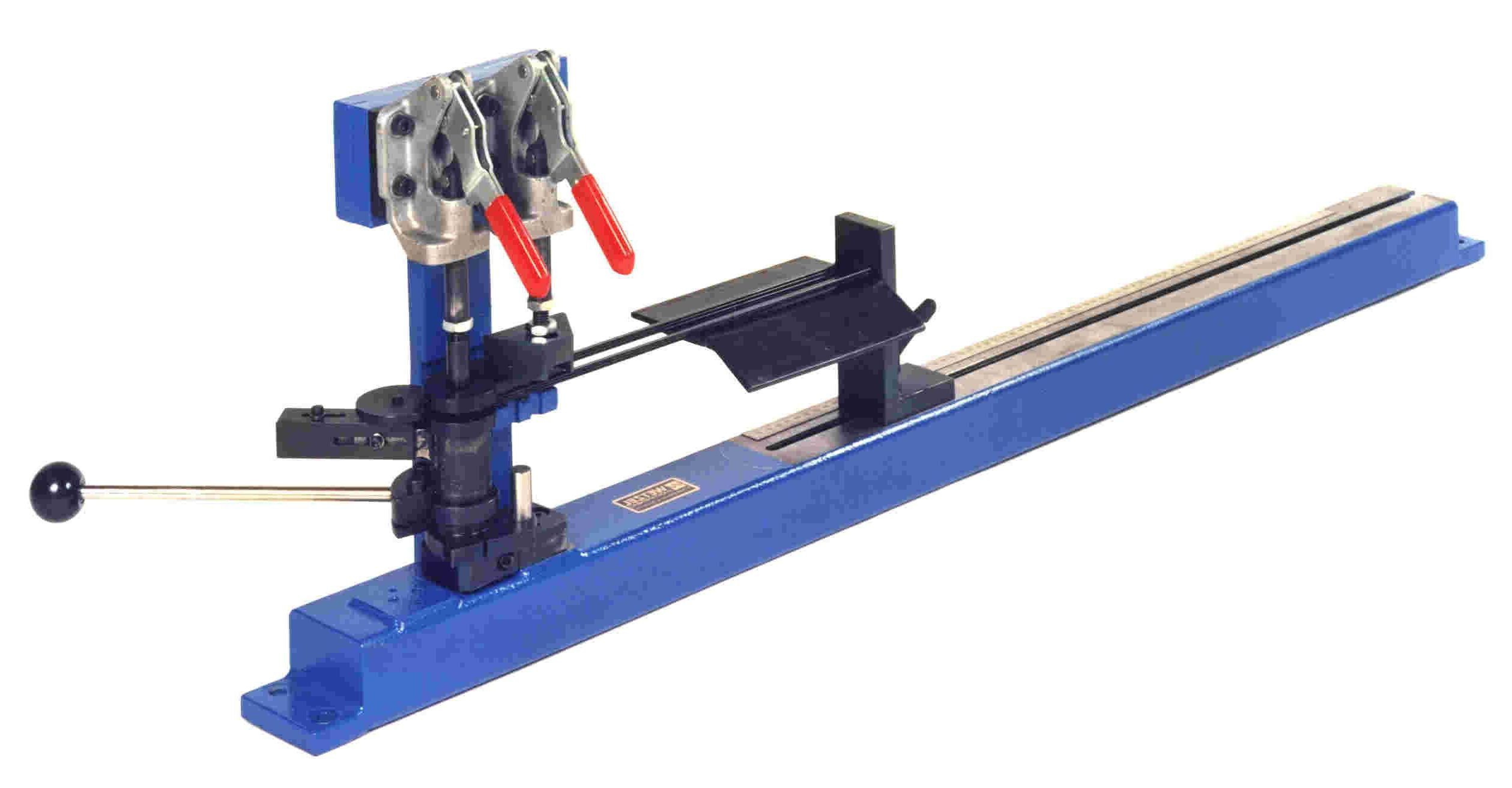

| 2.058.05 | Table for bending device |

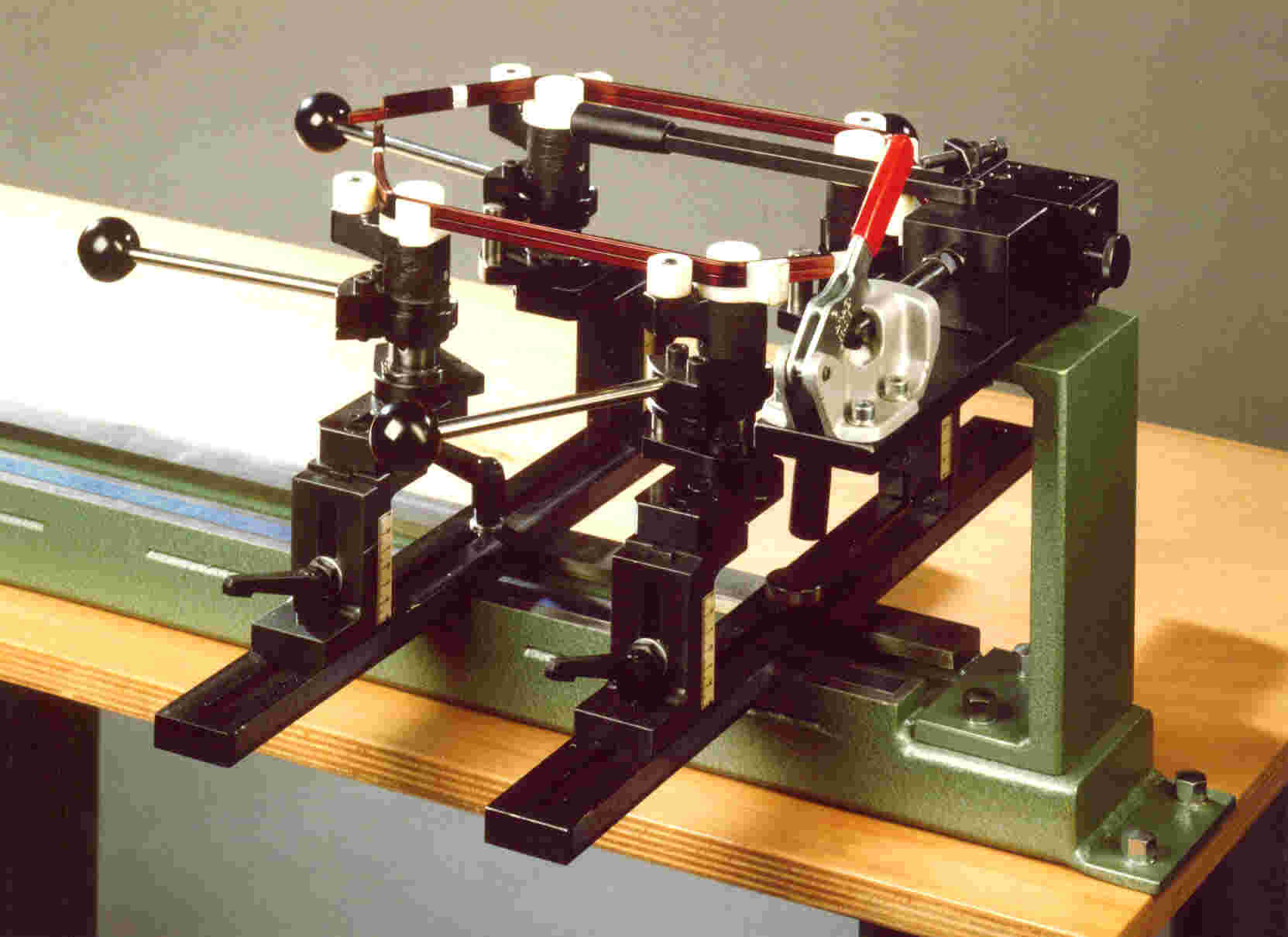

| 2.058.10 | Hairpin bending device with standard accessories: Bending diameter 10 x 3 mm high Bending diameter 10 x 6 mm high |

| 2.058.20 | Interchangeable bending diameter (specify diameter and height when ordering) |

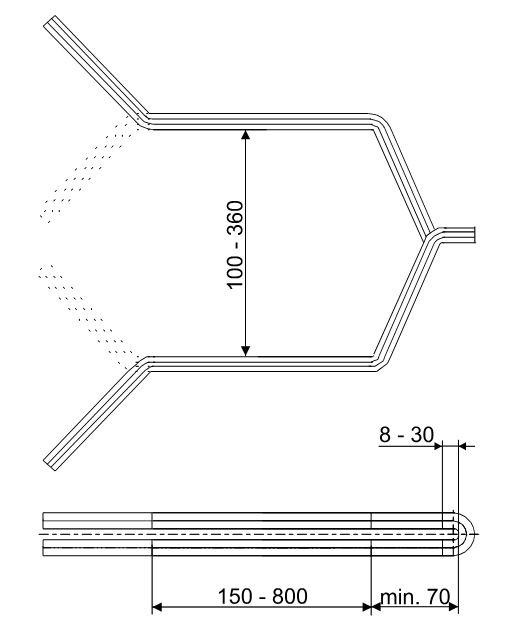

| 2.058.50 | Bending device for end windings without switching ends (total 4 bends) |

| 2.058.60 | Bending device for winding head and switching ends (wave and loop winding) (total 6 bends) |

| 2.058.62 | Support table, height-adjustable for placing and manually bending the soldering lugs of preformed coils in wave or loop winding |

| 2.058.80 | Pneumatic bending device for the involute |

| 2.058.80.2 | Manual leg press unit attached to the involute bending machine |